Hydrogen Deuterium Exchange

From LEAP

(→Contact LEAP) |

|||

| Line 12: | Line 12: | ||

'''Hydrogen Deuterium Exchange (HD-x)''' is an experimental technique to obtain structural data on proteins. It relies on the accurate measurement of the degree of labeling of the protein by deuterated hydrogen during a precisely measured labeling interval. The labeling reaction is stopped by addition of a quenching reagent, and loss of label between the quench step and analysis (usually by LCMS) is minimized by keeping the reactants at a temperature close to zero degrees Celsius. <br/><br/> | '''Hydrogen Deuterium Exchange (HD-x)''' is an experimental technique to obtain structural data on proteins. It relies on the accurate measurement of the degree of labeling of the protein by deuterated hydrogen during a precisely measured labeling interval. The labeling reaction is stopped by addition of a quenching reagent, and loss of label between the quench step and analysis (usually by LCMS) is minimized by keeping the reactants at a temperature close to zero degrees Celsius. <br/><br/> | ||

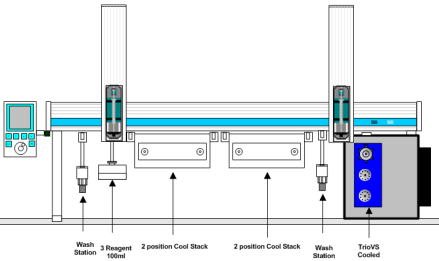

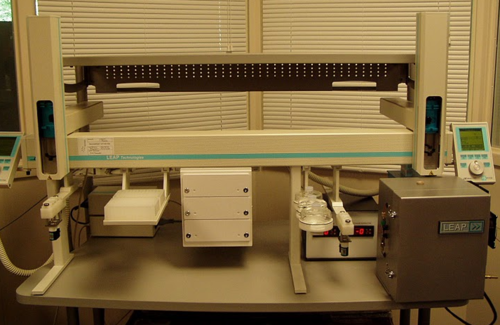

The technique is difficult to perform manually due to the demands for precise timing and reproducing exactly the same experimental conditions. Automation solves both of these challenges. [http://www.leaptec.com/ LEAP Technologies] has developed a robotic solution to the sample prep and introduction to the LCMS. It consists of a [http://www.leapwiki.com/mediawiki/index.php?title=TwinPAL Twin PAL] workstation configured as shown below. There are two cooled zones on the workstation: A [http://www.leapwiki.com/mediawiki/index.php?title=Single_Drawer_Cooler cooled stack] at 1oC for the samples and labeled reactants and a [http://www.leapwiki.com/mediawiki/index.php?title=Valve_Cooler cooled chromatography module] which contains the injection valve, the [http://www.leapwiki.com/mediawiki/index.php?title=Valve_Switching_Modules column selection valves]and the columns themselves. These are maintained also at around 1degree C. Recently, LEAP has introduced a version for [http://www.leapwiki.com/mediawiki/index.php?title=UPLC UPLC] using the [http://www.leapwiki.com/mediawiki/index.php?title=TRIOVS TRIOVS valving system]. The automation process is controlled using [http://www.leapwiki.com/mediawiki/index.php?title=Category:LEAP_Shell LEAP Shell] software. <br/><br/> | The technique is difficult to perform manually due to the demands for precise timing and reproducing exactly the same experimental conditions. Automation solves both of these challenges. [http://www.leaptec.com/ LEAP Technologies] has developed a robotic solution to the sample prep and introduction to the LCMS. It consists of a [http://www.leapwiki.com/mediawiki/index.php?title=TwinPAL Twin PAL] workstation configured as shown below. There are two cooled zones on the workstation: A [http://www.leapwiki.com/mediawiki/index.php?title=Single_Drawer_Cooler cooled stack] at 1oC for the samples and labeled reactants and a [http://www.leapwiki.com/mediawiki/index.php?title=Valve_Cooler cooled chromatography module] which contains the injection valve, the [http://www.leapwiki.com/mediawiki/index.php?title=Valve_Switching_Modules column selection valves]and the columns themselves. These are maintained also at around 1degree C. Recently, LEAP has introduced a version for [http://www.leapwiki.com/mediawiki/index.php?title=UPLC UPLC] using the [http://www.leapwiki.com/mediawiki/index.php?title=TRIOVS TRIOVS valving system]. The automation process is controlled using [http://www.leapwiki.com/mediawiki/index.php?title=Category:LEAP_Shell LEAP Shell] software. <br/><br/> | ||

| + | |||

| + | |||

| + | [[image:As Seen.PNG |100px|left|As Seen at LEAP]] | ||

| + | [[image:ASMS_2010.png |300px|left|As seen at ASMS 2011]] | ||

=== Significant Markets === | === Significant Markets === | ||

| Line 151: | Line 155: | ||

[[image:As Seen.PNG |100px|left|As Seen at LEAP]] | [[image:As Seen.PNG |100px|left|As Seen at LEAP]] | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

=== Contact LEAP === | === Contact LEAP === | ||

{{contact|topic=LEAP and the PAL Platform}} | {{contact|topic=LEAP and the PAL Platform}} | ||

Revision as of 15:41, 2 June 2011

| Hydrogen Deuterium Exchange |

| Application Type | |

| SPECIAL | |

| Application ID | |

| HD-X PAL | |

| Description | |

| Automated Sample Prep for HD-X |

General Description

Hydrogen Deuterium Exchange (HD-x) is an experimental technique to obtain structural data on proteins. It relies on the accurate measurement of the degree of labeling of the protein by deuterated hydrogen during a precisely measured labeling interval. The labeling reaction is stopped by addition of a quenching reagent, and loss of label between the quench step and analysis (usually by LCMS) is minimized by keeping the reactants at a temperature close to zero degrees Celsius.

The technique is difficult to perform manually due to the demands for precise timing and reproducing exactly the same experimental conditions. Automation solves both of these challenges. LEAP Technologies has developed a robotic solution to the sample prep and introduction to the LCMS. It consists of a Twin PAL workstation configured as shown below. There are two cooled zones on the workstation: A cooled stack at 1oC for the samples and labeled reactants and a cooled chromatography module which contains the injection valve, the column selection valvesand the columns themselves. These are maintained also at around 1degree C. Recently, LEAP has introduced a version for UPLC using the TRIOVS valving system. The automation process is controlled using LEAP Shell software.

Significant Markets

- Pharmaceutical - Drug Discovery

- Academia - Protein structural studies

Protein Structure

Protein function is strongly related to their tertiary structure and conformation. Chemical interactions which change this conformation can significantly affect protein functionality. This is important in studying disease states or effectiveness of drug candidates.

There are 3 commonly used techniques to study protein structure:

1. Crystallography

2. NMR

3. HD Exchange

HD Exchange is a good approach in cases where there is insufficient sample (NMR) or the protein will not crystallize. It relies on the accurate measurement of the degree of labeling of a protein by deuterated hydrogen during a precisely measured labeling interval. The deuterium is exchanged with hydrogen atoms on the exposed amide backbone of the protein and depending on the which regions are exposed and how the protein is folded, differences are seen in the MS spectra of the digested protein when compared with non-labeled proteins.

Labeling time is important (exposure time of the protein to Deuterium) as is prevention of "back-exchange" after the labeling has occurred. This is the natural tendency of normal hydrogen to replace the deuterium after the label is removed. This is minimized by reducing the temperature of the mixture to close to zero degrees Celsius.

What is an HD-X experiment ?

Performing H/D exchange experiments manually involves setting up many labeling mixtures then quenching these mixtures at precisely timed intervals (by changing the pH) and then injecting them onto a chilled injection valve to the LCMS. In most cases a range of label times is used, from 10 seconds to several hours. Sources of error (apart from normal liquid handling inaccuracies) are timing errors, and degradation of sample due to "back-exchange". All of these sources of error are eliminated using the automated system described here.

Overview of H/D-x PAL System

H/D-X PAL™ is an easy-to-use, system that provides an automated process for the scheduling and experimental execution of H/D-X experimental workflow. By use of the advanced LEAP Shell scheduling software experimental design is simplified and reliable. Synchronous reagent addition and sample labeling steps are automatically scheduled to increase throughput and produce high quality data.

What does the H/D-X PAL do?

The instrument has two cooled zones for sample storage and labeling. The injection valve is chilled to 1 degree Celsius and includes a solvent pre-chiller and column selection valve for in-line protein digestion.

A typical experiment would consist of around a dozen time points for each protein sample, ranging from 10 seconds to 8 hours. The PAL system will schedule the experiments and perform each of the following 3 steps for each time point and sample:

Labeling The protein is mixed with a Deuterium reagent and incubated for a precisely timed interval at room temperature.

Quenching The labeling reaction is stopped by transferring a volume of the mixture to an excess of quenching reagent in a pre-cooled vessel.

Injection A measured portion of the quenched reactants is injected into a multi-column, multi-valve LCMS system. This step is synchronized with the analytical system using hardware signals. The PAL will inject samples as the LCMS system becomes ready. Labeled and quenched reactants are held in the cooled stack until they have been injected and analyzed.

Software Control

LEAP has developed a scheduling application using their proprietary software LEAP Shell which will automate the above labeling steps, as well as the injection to the MS and the associated chromatography.

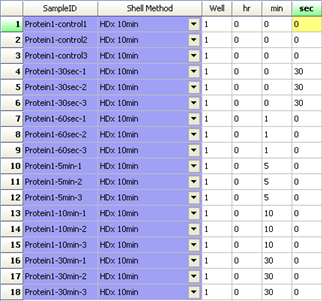

LEAP Shell Screen Shot 1: User interface to set up the labeling experiment:

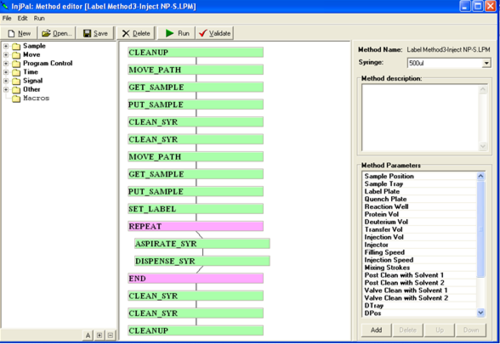

LEAP Shell Screen Shot 2: Powerful editor for the PAL Methods:

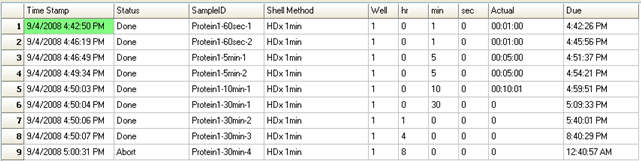

LEAP Shell Screen Shot 3: Run-time display of the labeling experiment with actual times:

Key features of the Hydrogen Deuterium scheduler application

- No need for the operator to worry about timing conflicts for the labeling steps. These are resolved by the program on the fly.

- Easy entry of the labeling experiments in ascending order of labeling time.

- No limit to the number of protein samples which can be handled in a single experiment.

- Run-time display of the measured labeling time next to the requested labeling time.(accuracy is within 1 second).

- Run-time display of the status of each sample as it progresses through the experiment. e.g. “Labeling”, “quenched”, “injected”.

- The speed of the PAL is monitored by the program and timing adjustments are made on the fly to maintain incubation accuracy. (e.g. No need to worry about timing if PAL wash parameters change.)

- Logfile output of all experimental conditions and the actual labeling and injection times of each sample.

- Long labeling time experiments are automatically set up first, to get the process started as soon as possible.

- Samples are injected as the LCMS system comes ready. LC runtime does not impact the efficiency of the labeling experiments.

- Can be integrated with the following data systems: Analyst 1.4.2, Xcalibur, ChemStation.

Why Automate?

- Minimize variability

- Better quality data

- Higher confidence in results

- Walk-away convenience

- Overnight experimental runs

- More time for data analysis

- Software control of complex timing

- Allows more data points

- Multiplexing of several proteins in one experiment

What are the challenges?

- Temperature Control

- Quenching at low temp

- Digestion and Separation at Low temp

- Precise Timing

- Labeling series should be handled non-sequentially

- Scheduling algorithm to avoid conflicts

- Synchronization of steps with detection system

- Liquid Handling

- Volumes range from 5ul to 5ml

- Precision

Useful links

![]() HXMS.com A good general reference site on HD Exchange theory and practice

HXMS.com A good general reference site on HD Exchange theory and practice

![]() ASMS Interest Group - Hydrogen Exchange and Covalent Labeling

ASMS Interest Group - Hydrogen Exchange and Covalent Labeling

![]() LEAP Website H/D-x product description

LEAP Website H/D-x product description

Publications

![]() American Chemical Society 2006. Chalmers

American Chemical Society 2006. Chalmers

![]() Poster from ASMS 2006

Poster from ASMS 2006

![]() Poster ASMS 2006 Washington Univ. In St Louis

Poster ASMS 2006 Washington Univ. In St Louis

Other Reference material

![]() LEAP HDX Application Note

LEAP HDX Application Note

![]() Collaboration between LEAP & ExSAR

Collaboration between LEAP & ExSAR

![]() Comparison of Data Processing software

Comparison of Data Processing software

Unique Solutions

HD-X with Waters Valves and Injector

HD-X with ambient tray holder and 3 drawer cooled stack

Videos of PAL

![]() LEAP's PAL Application Videos on YouTube

LEAP's PAL Application Videos on YouTube

![]() Proteomics Movie on YouTube

Proteomics Movie on YouTube

Hydrogen Deuterium exchange (HDX)or (HDE)is a Mass Spec technique which compares the amount of Deuterium which remains bound to the backbone of protein fragments after various stages of digestion and labeling. This information can be extrapolated by powerful data processing software into a map showing which parts of the proteins are exposed and which are shielded from the surrounding hydrogen in aqueous solution. This data provides valuable information about the protein structure and the effects of various ligand binding reactions on structure. It offers unique information which cannot currently be obtained by other techniques such as NMR or crystallography. Even now, most H/D-exchange experiments are performed only in academic institutions with all the sample preparation, labeling, digestion steps and injections done manually. The technique has been slow to catch on because such experiments are considered quite difficult to perform well. Significant inaccuracies occur due to imprecision of timing and temperature. LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions. Keywords: Protein structural studies, Deuterium labeling, Epitope mapping, Covalent labeling, NMR, Crystalography

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |

LEAP Technologies provides fully automated sample processing workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography. LEAP also offers process control systems and stand alone workstations. LEAP offers full support and service for the PAL platform with over 11 years of history with the PAL. LEAP can also write custom macros, cycles, and scheduling software for your specific applications. We're proud that LEAP is known as a productivity improver for laboratories including government labs in agencies such as FDA, USDA, EPA, FBI, Armed Forces, Homeland Security and others function more efficiently. Robotic sample prep equipment works well in government labs and challenges lab technicians to keep feeding those more samples. Analytical equipment such as chromatographs and mass spectrometers are expensive devices and also expensive to maintain. LEAP can help to keep them running and analyze samples around the clock. LEAP has most of its laboratory automation robots under GSAcontract and is eager to service and maintain everything it sells to keep your expensive lab equipment running around the clock. LEAP offers customized on-site training.LEAP Is continuing to develop FAQ, Solutions, Tips & Techniques,a Learning Center with the LEAP Wiki for the benefit of all PAL Platform Robotic users. Our aim is to be the ultimate knowledge base on everything related to the PAL. LEAP has extensive multi-vendor experience with integrating the PAL. We have the Quality, Training, Parts availability, Infrastructure, and Experience.LEAP is sometimes referred to as an Application Automation House who is continually adding new products and solutions to its Lab Automation line. As we do so we change the content of this web site so please check back.

Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions whether it is our standard applications or customized to your needs. LEAP provides automation that fits your needs and reduces errors, increases sample capacity, increases efficiency, reduces cost by supplying long term productivity improvements with user friendly software and flexible hardware.Customize your PAL robotic platform with LEAP Technologies.