Sharper peaks using 2-stage low sample dispersal injection technique

From LEAP

For low dispersion of the sample (no tailing in the loop), and to meter a very small volume of sample very precisely into the flow, the customer wanted to use the valve to do a " heart cut" or metered injection of the sample by toggling the injection valve at the same time the syringe is injecting very slowly.

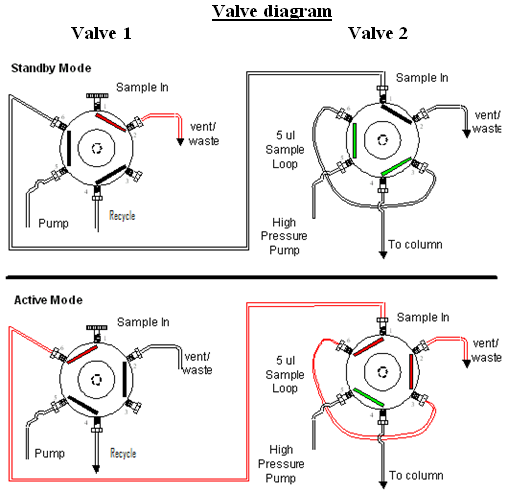

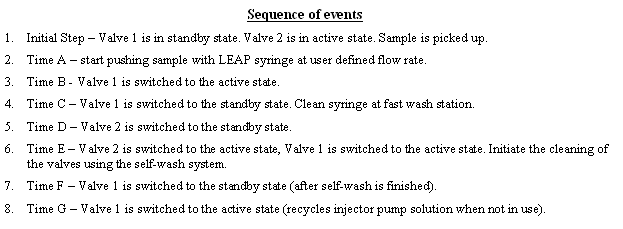

The PAL will function in a manner similar to a UPLCsystem. The HTS PAL will use two 6-port Cheminert valves to perform this process. An injection will be made to Valve 1. A injector pump will be plumbed up to Valve 1 with a very low flow rate (i.e. 5ul/second). Once the sample is loaded into Valve 1, the loop will switch for an amount of time determined by the operator.

The goal will be to transfer 0.5ul of sample from the syringe to the center of the 5ul loop on Valve 2. To transfer the sample slug correctly, the operator will be able to manipulate three variables. Those variables will be (1) the flow rate of the injector pump, (2) the period of time Valve 1 will be switched to load the sample from the loop to the injector pump flow line, and (3) the amount of time the injector pump will allowed to pump the sample to the 5ul loop of Valve 2. Once the sample is centered in the 5ul loop of Valve 2, the valve will be switched and the sample will be pumped through the column and to the HPLC detector using a LC system.

Contents |

Additional Reference Material

![]() Powerpoint of customer publication Multi-Stage Sample Injection: An Effective Way to Reduce Band Broadening in Liquid Chromatography

Powerpoint of customer publication Multi-Stage Sample Injection: An Effective Way to Reduce Band Broadening in Liquid Chromatography

Project Ref: H1103

For other cost/time saving measures consider:

- LEAP offers multiple choices of Valve Self Wash Stations to aid in cleaning the valve [1]

- Dual Channel Serial Injection with Front Cut (M-002) using Analyst and ICC-CE [2]

- Dual Channel Parallel Injection (M-003) using Cycle Composer Software and Analyst [3]

- “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [4]

- Dual Channel Parallel Injection (M-005) using LEAP Shell software [5]

- Summary of LC Multi Valve Applications [6]

- LEAP Shell Software and application for custom injections and scheduling [7]

Videos of PAL

![]() LEAP's PAL Application Videos on YouTube

LEAP's PAL Application Videos on YouTube

LEAP strives to find total solutions for analytical lab automation by automating analytical processes for small and large molecules in extracted liquids, solids, and recently in human, animal and plant tissues. We provide the precise robotics and efficient sample prep required by modern measurement techniques such as MALDITOF mass spectroscopy. Our newest specialty customization of CTC Analytics’ PAL features small workstations that can perform complex liquid handling tasks including HPLC-Purification, SPE, filtration, weighing, heating and stirring. They can be configured as stand alone units or integrated for “just in time” sample prep for LC-MS or GC-MS analysis.

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |