Small Volume Fraction Collection

From LEAP

(→Videos of PAL) |

|||

| Line 123: | Line 123: | ||

[[image: Info icon.png|40px]] [[:Media:Animate_Cartoon_explaining_Collection.pps | Slideshow displaying stages for ZERO LOSS, ZERO DRIP Move and Collection ]]<br> | [[image: Info icon.png|40px]] [[:Media:Animate_Cartoon_explaining_Collection.pps | Slideshow displaying stages for ZERO LOSS, ZERO DRIP Move and Collection ]]<br> | ||

=== Videos of PAL === | === Videos of PAL === | ||

| + | <br> | ||

| + | [[Image:Movie Icon.png|40px]] | ||

| + | [http://www.youtube.com/user/LEAPTechnologies#p/u/13/vGX6L6a14Sc Purification Video on YouTube] | ||

<br> | <br> | ||

[[Image:Movie Icon.png|40px]] | [[Image:Movie Icon.png|40px]] | ||

| Line 128: | Line 131: | ||

<br> | <br> | ||

---- | ---- | ||

| + | |||

{{logo}} | {{logo}} | ||

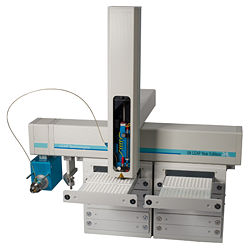

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions. | LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions. | ||

Revision as of 16:45, 14 June 2010

| Small Volume Fraction Collection -- Collect PAL |

| Application Type | |

| Fraction Collection | |

| Application ID | |

| CP1.1 | |

| Description | |

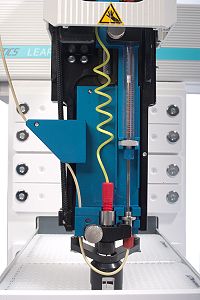

| “0” Loss, “0” Drip Fraction Collection using a LEAP designed inverted syringe equipped with a hollow plunger and custom syringe holder. This unique and patent-pending design allows for collection to continue during well-to-well movements. Typical Applications involve isolating and collecting sample into precoated scintillation plates (Luma Plate by Perkin Elmer for instance) with a finely tuned collection of the sample into the wells of a plate. With this data a metabolite profile can be reproduced with the plate data as read by a scintillation counter. (See: Scintillation Counter)

The integration of the Collect PAL with LC-MS and UPLC systems is achieved via LEAP Shell and the Collect PAL application. |

Overview

The Collect PAL was designed through collaborative efforts with researchers at BMS (Princeton) and Merck-Frosst (Montreal). Initial instrument parameters defined a simple fraction collector application capable of collecting into 96-well plates for radiolabeled metabolite collection and identification. Very quickly it became apparent that the modern biotransformation laboratory required a more rigorous and precise application and instrument – especially due to the presence of radiolabeled compounds and the risk of unnecessary exposure. The use of precoated plates required that the sample be delivered accurately and not evaporate during the process on the walls of the well (poor readings can result from improperly prepared plates and in this case evaporation of the compound on the walls of the well does not allow the compound to absorb onto the scintillant in the well). What resulted is an instrument that has a "No Loss, No Drip" operation and an easy to use, fully operator-designed interface.

The Collect PAL offers environmental control (CoolStacks offered by LEAP) for samples and the precision to deliver into a 384-well plate at 3 sec/well. With the use of two, 6-drawer Stacks, 24 microtiter plates can serve as fraction sites (up to 9216 fraction sites available). With appropriate conditions the Collect PAL can pierce septa, plate seals, or capmats and deliver the sample into the well.

At the 2008 ISSX Meeting held in San Diego, California, colleagues from BMS presented their findings on the Collect PAL. (See poster and ppt file in Other Reference Material Section). The responses from the research community have been very positive. With the help and insight of the researchers we have made several modifications to the original design that make the Collect PAL more compatible with the small volume collection specifications. Results from our collaborations pushed us to collection into 384-well plates with documented 3sec/well collection. Our customers have integrated the Collect PAL with leading UPLC systems as well as HPLC-MS and on-line radioactivity flow detectors-LC systems.

Flexibility and convenience are two additional factors that make the Collect PAL instrument easy to use. Based on the HTC PAL, the Collect PAL occupies only 30"x30" of bench space and needs only 30" height clearance. Defined parameters of delay time, collection time per well, and number of fractions to collect are all user determined.

Significant Markets and Research Focus

- Metabolic Profiling Groups

- DMPK

- Radiolabel Compound Characterization

- ADMET

- Metabolomics

- Impurity Identification

LEAP's Approach

The Collect PAL is designed to accommodate the needs of the researcher with valuable samples and small volume collection requirements. With our innovation and collaborations we have introduced an instrument that loses no sample during the defined collection time window and can distribute the desired sample volume into wells accurately and as quickly as 3sec/well. "No Loss" sample collection continues even during a well-to-well move. The efficiency and effectiveness of this design is unique and is not possible with other syringe, solenoid, or drop collector options.

Most market fraction collectors can be dissected into two camps – drop or solenoid collectors.

Drop Collectors do just that; i.e. drip or flow or spray sample out of a tube and into a vessel. During the collection time window the flow rate is diverted to an outlet (usually a needle or even just tubing) that is hovering over an open collection vessel. Flow is never stopped during the time window and chances are very good that some percentage of the drops or flow or spray will not hit a well during a “move to next well” command from the fraction collector software. Sample can contaminate the instrument, plate, etc.

Solenoid Based fraction collectors offer no drip between sites, yet sample is lost during the “move to next well” command. For that brief time span that the head moves from well-to-well the solenoid is deactivated and flow goes into the waste stream. The head moves over the next vessel and the solenoid is activated back to the collection path. Sample is lost during every move during collection and is, for the most part unrecoverable.

Neither type of typical fraction collector can be easily set up to collect through a covered plate or through septa covered vials. To do this an extra Z-Motion is required and the fraction collector needs a piercing needle, a push off component, and time to accomplish the task.

The Collect PAL features penetration and retract parameters that allow the needle to go below the “surface” plane of the plate for the first second of collection and then retract slightly, but not above the seal to complete the "seconds per well" collection time. This allows the collection to occur in a completely sealed plate and provides even greater protection of the sample.

As our user numbers grow we find that our modularity and flexibility also continue to grow. We are already working on version 2 of the Collect PAL series.

Software Control

The Collect PAL operates under a LEAP Shell application and coordination via contact closures with LC systems.

PHOTOS of Configurations

LEAP Shell Screenshots

Video

![]() Collect PAL in action on YouTube

Collect PAL in action on YouTube

![]() Various PAL's in action on YouTube

Various PAL's in action on YouTube

LEAP Marketing Material

Starting Points for Method Development Work for the Researcher with Collect PAL from LEAP

![]() Brief Study on Collect PAL Settings 40 Asp Variable Dsp, Variable Flow Rates, Variable Plunger

Brief Study on Collect PAL Settings 40 Asp Variable Dsp, Variable Flow Rates, Variable Plunger

![]() Brief Study on Collect PAL Settings 60 Asp Variable Dsp, Variable Flow Rates, Variable Plunger

Brief Study on Collect PAL Settings 60 Asp Variable Dsp, Variable Flow Rates, Variable Plunger

![]() Brief Study on Collect PAL Settings 80 Dsp, Variable Dsp

Brief Study on Collect PAL Settings 80 Dsp, Variable Dsp

![]() Brief Study on Collect PAL Settings 90 Dsp, Variable Dsp

Brief Study on Collect PAL Settings 90 Dsp, Variable Dsp

![]() Brief Study on Collect PAL Drawer Study 2.5 sec Collection, Variable Flow Rates, Variable Plunger

Brief Study on Collect PAL Drawer Study 2.5 sec Collection, Variable Flow Rates, Variable Plunger

![]() Brief Study on Collect PAL Drawer Study 5 sec Collection, Variable Flow Rates, Variable Plunger

Brief Study on Collect PAL Drawer Study 5 sec Collection, Variable Flow Rates, Variable Plunger

![]() Brief Study on Collect PAL Settings Settings 5mm Penetrate and 2mm Retract, Variable Flow Rates, Variable Plunger

Brief Study on Collect PAL Settings Settings 5mm Penetrate and 2mm Retract, Variable Flow Rates, Variable Plunger

Useful Links, Resources, and References

![]() American Society for Mass Spectrometry

American Society for Mass Spectrometry

![]() International Society for the Study of Xenobiotics

International Society for the Study of Xenobiotics

Other Reference Material

![]() 2008 ISSX BMS Poster

2008 ISSX BMS Poster

![]() Extended Mix - 2008 ISSX BMS Poster

Extended Mix - 2008 ISSX BMS Poster

![]() Slideshow displaying stages for ZERO LOSS, ZERO DRIP Move and Collection

Slideshow displaying stages for ZERO LOSS, ZERO DRIP Move and Collection

Videos of PAL

![]() Purification Video on YouTube

Purification Video on YouTube

![]() LEAP's PAL Application Videos on YouTube

LEAP's PAL Application Videos on YouTube

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |