Large Volume Dispensing

From LEAP

(→Overview) |

Current revision (20:48, 8 June 2010) (view source) (→Typical applications) |

||

| (3 intermediate revisions not shown.) | |||

| Line 8: | Line 8: | ||

{{logo}} | {{logo}} | ||

=== Overview === | === Overview === | ||

| - | There are currently | + | There are currently multiple [http://www.leaptec.com/ LEAP Technologies] preferred options on the [http://leapwiki.com/mediawiki/index.php?title=Category:PAL PAL] for delivery of large volumes of solvent. Choice will depend on the requirements for delivery rate, delivery volume and accuracy. In each case these pumps can dispense liquid either through PAL side-port syringe, or using the LEAP "Dispense Tool" accessory. The advantage of the latter is that it permits larger flow rates and includes a venting channel to avoid over pressurization in the case of filling sealed vessels. A PAL controlled selector valve can supply multiple reagents thru the same dispense port. |

=== Common Uses === | === Common Uses === | ||

| Line 16: | Line 16: | ||

* Dilutions | * Dilutions | ||

| - | * | + | * [http://www.leapwiki.com/mediawiki/index.php?title=Category:Derivatization Derivatization] |

* Sample spiking | * Sample spiking | ||

* Standard additions | * Standard additions | ||

| Line 63: | Line 63: | ||

The Mini Pump liquid handling pump is a syringe-free pump capable of delivering a bidirectional flow to six orders of magnitude. The Mini Pump is a positive displacement pump, which means that it is self-priming and tolerant of any gas which may find its way into the fluid lines. Since there is no separate fill cycle, the pump can be operated continuously, and volumetric capacity is limited only by time. | The Mini Pump liquid handling pump is a syringe-free pump capable of delivering a bidirectional flow to six orders of magnitude. The Mini Pump is a positive displacement pump, which means that it is self-priming and tolerant of any gas which may find its way into the fluid lines. Since there is no separate fill cycle, the pump can be operated continuously, and volumetric capacity is limited only by time. | ||

| - | The range can be from less than 1 ul to over 25 mL/min | + | The flow range can be from less than 1 ul to over 25 mL/min |

''' Notes ''' | ''' Notes ''' | ||

| Line 78: | Line 78: | ||

---- | ---- | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

=== Side Port Syringe Accessory === | === Side Port Syringe Accessory === | ||

Current revision

| Large Volume Dispensing |

| Application Type | |

| SPECIAL | |

| Application ID | |

| Description | |

| Accurate dispensing of solvents at high flow rates |

Contents |

Overview

There are currently multiple LEAP Technologies preferred options on the PAL for delivery of large volumes of solvent. Choice will depend on the requirements for delivery rate, delivery volume and accuracy. In each case these pumps can dispense liquid either through PAL side-port syringe, or using the LEAP "Dispense Tool" accessory. The advantage of the latter is that it permits larger flow rates and includes a venting channel to avoid over pressurization in the case of filling sealed vessels. A PAL controlled selector valve can supply multiple reagents thru the same dispense port.

Common Uses

- Dispense liquid prior sample injection and combines the "add liquid" and "inject" steps without user intervention or syringe change.

Typical applications

- Dilutions

- Derivatization

- Sample spiking

- Standard additions

Dilutor Accessory

Can feed a solvent through the injection syringe into sample plates or vials

There are multiple options on the PAL for delivery of volumes of solvent. Choice will depend on the requirements for delivery rate, delivery volume and accuracy.

Syringe pump volume range of 0.25 ml to 2.5ml delivery per 2.5 ml syringe cycle. (Optional dilutor syringe 1ml or 5 ml)

Flow Rate Range: 10μl/min - 300μl/min

Wetted parts: All liquids compatible with borosilicate glass, PTFE, Kel-F, FEP

Notes

- Requires the addition of a custom macro or cycle for dispensing/diluting applications

- Can be used with any of the PAL side port syringes or with the DISPENSE Tool

- Is not supported by the on board PAL cycles

- Requires an open AUX Port on the PAL

- Requires PAL firmware 2.3 or higher

Syringe pump volume range of 0.25 ml to 2.5ml delivery per 2.5 ml syringe cycle. (Optional dilutor syringe 1ml or 5 ml)

Flow Rate Range: 10μl/min - 300μl/min

Wetted parts: All liquids compatible with borosilicate glass, PTFE, Kel-F, FEP

Notes

- Requires the addition of a custom macro or cycle for dispensing/diluting applications

- Can be used with any of the PAL side port syringes or with the DISPENSE Tool

- Is not supported by the on board PAL cycles

- Requires an open AUX Port on the PAL

- Requires PAL firmware 2.3 or higher

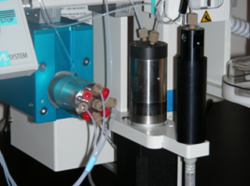

Mini Pump Series Accessory

The Mini Pump liquid handling pump is a syringe-free pump capable of delivering a bidirectional flow to six orders of magnitude. The Mini Pump is a positive displacement pump, which means that it is self-priming and tolerant of any gas which may find its way into the fluid lines. Since there is no separate fill cycle, the pump can be operated continuously, and volumetric capacity is limited only by time.

The flow range can be from less than 1 ul to over 25 mL/min

Notes

- Requires LEAP Shell Software for control.

- Can be used with any of the PAL side port syringes or with the DISPENSE Tool

- Is not supported by the onboard PAL cycles

Side Port Syringe Accessory

Main Features

- Can be used to dispense liquid prior sample injection

- Combines the "add liquid" and "inject" steps without user intervention or syringe change

- Variety of sizes available: 20µl or 80µl for LC applications and 20µl or 80µl for GC applications

DISPTool Accessory

Main Features

- Can be used to dispense bulk liquids without using the injection syringe

- The tool is magnetically picked up by the PAL and moved to the vial or plate only when needed

- Able to pierce a septa with an adjustable needle penetration

- 19ga needle with built in vent

- May allow single rail to have functionality of dual rail system

- Can be used with the Dilutor, Mini Pump, or LEAP SDS

Requirements/Limitations

- Requires some additional rail space for DISPTool parking location

- Requires custom firmware

Video

![]() Dispense Tool movement Uses Windows Media Player to view

Dispense Tool movement Uses Windows Media Player to view

![]() Dispense tool in action on youtube

Dispense tool in action on youtube

![]() Various PAL's in action on YouTube

Various PAL's in action on YouTube

PRINT Function for Page

![]() PDF of this page formatted for printing

PDF of this page formatted for printing

LEAP strives to find total solutions for analytical lab automation by automating analytical processes for small and large molecules in extracted liquids, solids, and recently in human, animal and plant tissues. We provide the precise robotics and efficient sample prep required by modern measurement techniques such as MALDITOF mass spectroscopy. Our newest specialty customization of CTC Analytics’ PAL features small workstations that can perform complex liquid handling tasks including HPLC-Purification, SPE, filtration, weighing, heating and stirring. They can be configured as stand alone units or integrated for “just in time” sample prep for LC-MS or GC-MS analysis.

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |