M-001 Dual Channel Serial Injection - Analyst with ICC-CE

From LEAP

| LC Column Switching & Regeneration |

| Application Type | |

| SPECIAL | |

| Application ID | |

| M-001 | |

| Description | |

| LC Column Switching & Regeneration. |

Contents |

Overview

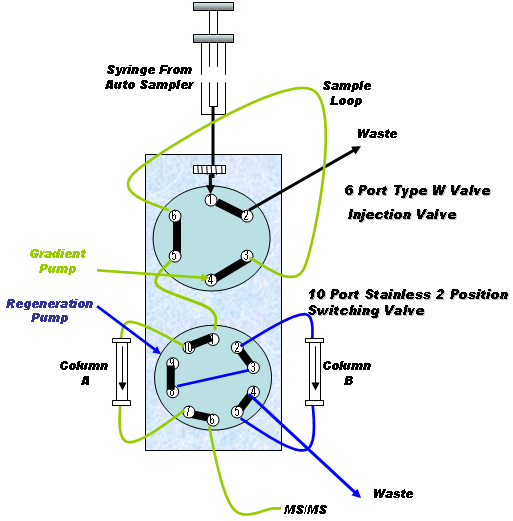

This configuration allows the regeneration of one of the analytical columns while the other one is engaged - giving greater efficiency and higher throughput. This is run directly from within Analyst® Software from Applied Biosystems Inc® using a LEAP Cycle (requires ICC-CE software).

There are 2 pumps needed, one for the gradient run and another (higher flow rate and isocratic) for regeneration. This configuration requires a 6 port valve for sample loading and a 10 port valvefor column switching. Both valves must be controlled by the LEAP cycle.

Please note: LEAP can not control the MS Selector valve as part of the cycle.

| Key Benefits |

| Saving of Reagent time (Back cut) |

| Increase throughput at little cost |

| Control is all within Analyst Software |

| Compliance not affected |

| GLP Compliant |

| Restrictions |

| Cannot do "Look Ahead" |

| Injections are not staggered |

| Peaks of interest must come off early |

| Columns may perform slightly different on alternating samples |

| Code | Application | Control SW | Key Hardware | Key Benefits | Restrictions | GLP |

|---|---|---|---|---|---|---|

| M-001 | Dual Channel Serial Injection Provides shorter cycle times by regenerating columns during next analytical run | Analyst with ICC-CE | * 6 port injection valve * 10 port Valve * Gradient Pump * Regeneration pump | * Saving of regeneration time(Back Cut) * Increase throughput at little cost * Control is all within Analyst * Compliance is not affected | * Can not do "Look Ahead" * Injections are not staggered * Peaks of interest must come of early * Columns may perform slightly differently on alternating samples | Yes |

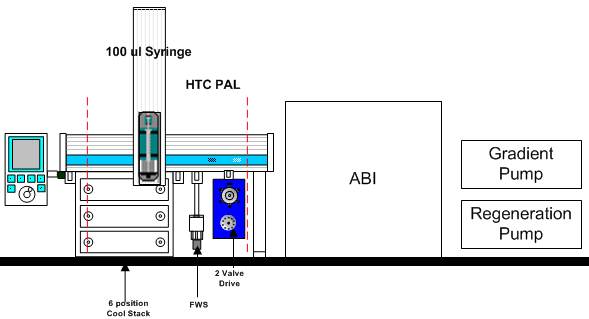

Typical System of PAL with CoolStack Fast Wash and Valves

When columns must be regenerated following each analysis, this technique permits automation of the process. While one column performs the analysis, the second column undergoes regeneration by use of an auxiliary pump. Once the first analysis is complete, the valve is switched and the regenerated column is now ready for analytical use.

PRINT Function for Page

![]() PDF Summary of Upgrade to Existing System

PDF Summary of Upgrade to Existing System

For other cost/time saving measures consider:

- LEAP offers multiple choices of Valve Self Wash Stations to aid in cleaning the valve

- Dual Channel Serial Injection with Front Cut (M-002) using Analyst and ICC-CE

- Dual Channel Parallel Injection (M-003) using Cycle Composer Software and Analyst

- “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software

- Dual Channel Parallel Injection (M-005) using LEAP Shell software

- Summary of LC Multi Valve Applications

- LEAP Shell Software and application for custom injections and scheduling

Accessories for the PAL

![]() Other Accessories for PAL Robots

Other Accessories for PAL Robots

This workstation application is based on the CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your LC or GC requirements. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible automation.

Contact LEAP

![]() Contact the LEAP office

Contact the LEAP office

Keywords: Dual Channel Serial Injection, Provides shorter cycle times by regenerating columns during next analytical run, Analyst with ICC-CE, 6 port injection valve, 10 port Valve, Gradient Pump ,Regeneration pump, Saving of regeneration time, Back Cut, Increase throughput at little cost, Control is all within Analyst, Compliance is not affected, Can not do Look Ahead, Injections are not staggered, Peaks of interest must come of early, Columns may perform slightly differently on alternating samples, ICC-CE software, cycles