Category:How to

From LEAP

PAL (commonly referred to as LEAP and CTC) is an X,Y,Z Robot with syringe only concept.

Included here are some basic how to info as a reference to go along with the training and orientation provided on-site or by phone by LEAP Technologies. It is intended to provide an overview for new users

and a reminder for infrequent users.

LEAP Syringe Replacement

How to Change the Syringe on the PAL

- Prime the replacement syringe manually. Use fresh (dry) solvent, and remove all bubbles.

- Place the syringe in the appropriate syringe adapter. Pull the plunger out to approximately 20% of its length

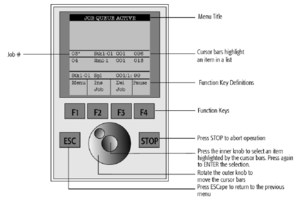

- On the LEAP Handheld, hit Menu (F1),

- Chang Syr (F1) the Injection Unit will move to a location that will facilitate installation of the syringe

- On the autosampler syringe arm, slide up the clear plastic cover.

- Near the top of the syringe, loosen the red knob by turning it to the right.

- Pinch together the pair of black needle guides that the needle slides through in normal use.

- With the needle guides pinched together, move the syringe(installed in the syringe adapter) partially into the Injection Unit. Guide the needle into the needle guides

- Place the plunger button into the plunger holder. Allow the syringe adapter to "click" into place by magnetic force, against the syringe carrier.

- Tighten the red knob against the syringe plunger by turning the knob to the left.

- Slide closed the clear plastic cover.

- On the LEAP Handheld, Press "Home" The plunger moves down until it hits the mechanical stop. This position is stored as the syringes zero volume position. Then the Injection Unit returns to the HOME position.

- After replacing a syringe, always check the needle penetration in the LC valve

![]() Changing the Syringe of the PAL

Changing the Syringe of the PAL

![]() Changing the Needle Sleeve of the PAL

Changing the Needle Sleeve of the PAL

![]() Manual Injection of the PAL

Manual Injection of the PAL

Cleaning the LEAP Syringe with Fast Wash Station

How to clean the syringe at the Fast Wash Station on the PAL

This can clean the needle or help remove a bubble from the syringe

- On the LEAP Handheld, hit Menu (F1)

- Clean Syr (F2) <enter>

- Select a Wash Station <enter>

- Enter the number of times the syringe should rinse <enter>

- On the LEAP Handheld, hit the ESC key (repeatedly if needed) to return to the top of the menu.

This option will move the LEAP syringe to the desired wash station and will rinse the full length of the syringe body. For new, or completely dry syringes, it is recommended to slightly pre-wet the syringe with solvent to displace some of the air.

Rinsing the Wash Station and Tubing with Solvent after refilling Solvent Reservoir

How to rinse the fast wash station solvent reservoirs

- To replenish the Wash solvent, close the stopcock at the base of the Wash Bottle

- Disconnect the tube at the black nut that goes into the white stopcock at the base of the bottle

- Rinse the bottle with fresh solvent and drain some solvent out through the stopcock

- Place the Wash bottle back into position, re-connect its tube, and open the stopcock

- On the LEAP Handheld, hit Menu (F1)

- Utilities <enter>

- Wash Station <enter>

- Select desired wash station <enter>

- Press Act Valve (F2) to open the valve (located in the solenoid under the Wash Station)

- Rinse the tube until all the bubbles in it are flushed out (several seconds)

- Press Deact Valve (F2) to close the solenoid valve

- When F2 reads Act Valve, the solenoid is closed

- When reads Deact Valve, the solenoid is open

- Hit the ESC key (repeatedly if needed) to return to the top of the menu.

Needle Penetration Adjustment for Injector Port

Adjusting the Needle Penetration of the Injector

- On the LEAP Handheld, hit Menu (F1)

- Setup, <enter>

- Objects, <enter>

- Injectors, <enter>

- LC V1v1, Z, <enter>, and set Z to 0 mm, <enter>

- Needle Penetr(ation), and set Needle Penetr to 0 mm or less, <enter>

- Hit Check Pos(ition) F1

- Choose Z, <enter>, and adjust it using the black needle guide as reference; save with <enter>

- Choose Needle Penetr(ation), <enter>, adjust to clunk, and back up 0.2 mm, <enter>

- Verify the Needle Penetr setting by

- Select Needle Penetr, <enter>, and listen for thunk; it might thunk a little, but not as badly. If it thunks badly, readjust the Needle Penetr till it thunks back up an additional 0.2 mm, and hit <enter>.

- Repeat this step as needed. It often takes several adjustments, but is then consistent.

- When adjusted, hit Movto Zero

- Hit the ESC key (repeatedly if needed) to return to the top of the menu.

![]() Changing the Injection Depth at Valve of the PAL

Changing the Injection Depth at Valve of the PAL

Switching the Valve

How to activate(toggle) the valve

- On the LEAP Handheld, hit Menu (F1)

- Utilities <enter>

- Injector <enter> (hit <enter> again to select default injector)

- Pressing Act Valve (F2) puts the valve in the red light Off position = injection port connected to loop (for at Type W valve)

- Pressing Deact Valve (F2) puts the valve in the red light On position = injection port not connected to loop (for at Type W valve)

- Hit the ESC key (repeatedly if needed) to return to the top of the menu.

Changing Trays

How to change the trays on the PAL

- On the LEAP Handheld, hit Menu (F1)

- Setup (F3) <enter>

- Objects <enter>

- Trays <enter>

- Select Desired Tray (usually Tray01, Tray02, Tray….) <enter>

- Scroll down to highlight ‘Tray Type’ <enter> and scroll through options

- VT54 – Vial Tray with 54 locations (blue)

- MT96 – Microplate Tray with 96 wells (short)

- DW96 – Deep Well tray with 96 wells (tall)

- Confirm/Adjust XYZ to coincide with Tray position 1 and well 1 (see detailed directions below)

- Be sure to save each coordinate

- Check the corners of the Tray

Setting Needle Penetration Depth for a Particular Tray Type

Changing the needle penetration for a specific tray type

Setting the Tray Holder XYZ position (performed at installation & described elsewhere) also enables the Needle Guide to find corner positions of a specified Tray (or well plate)

This procedure guides a user to select a Tray, then adjust the needle penetration for a vial resting in that Tray.

All of the XYZ positions for the Tray Holder, Wash Stations, Injector Port, and Waste should be calibrated prior to this procedure

Please note: only 1 needle penetration is available per tray type and is used for all positions of that tray type

- On the LEAP Handheld, hit Menu (F1)

- Utilities <enter>

- Tray (select Tray – Tray## or Stack - Stk1-##) <enter>

- Needle Penetr <enter>

- Start by entering a Needle Penetr depth of 0.0 mm <enter>

- Movto 001 (F3), Needle Penetr <enter>, Dial depth downward till downward syringe motion halts, back up 0.1 mm, <enter>

- Movto 009 (F3), Needle Penetr <enter>, Dial depth downward till downward syringe motion halts, back up 0.1 mm, <enter> (assumes VT-54)

- Movto 054 (F3), Needle Penetr <enter>, Dial depth downward till downward syringe motion halts, back up 0.1 mm, <enter> (assumes VT-54)

- Home

![]() Calibration of 96 well microtiter plate of the PAL

Calibration of 96 well microtiter plate of the PAL

This information is not meant to replace on-site familiarization but provide a basic outline of the steps involved. Please refer to your PAL owners manual for detailed information.

LEAP offers installation and familiarization training with every new system. The twelve month warranty includes unlimited telephone support and module exchange programs. Extended warranties include annual preventative maintenance in addition to telephone support and module exchange programs.

For customers that want to write their own custom macros and injection cycles, LEAP offers software training at our facility in Carrboro, NC.

For some videos you will be leaving the LEAPWiki and going to the MicroNMR Website. To return just press the back button in your browser window.

The videos are FLASH videos and should be easily viewed within any standard web browser. Simply click on one of the link to play that video. If you are having trouble viewing the videos you may need to install the Flash Plug-in from the Adobe website (www.adobe.com).

There is AUDIO so make sure your speakers are on!

MicroNMR a partner of LEAP Technologies has put together some basic Training Videos for the PAL robot

A special thanks to MicroNMR for providing the videos on their website for all to access http://www.micronmr.com/training_videos.html

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about How to with the PAL, please contact LEAP Technologies. |

Subcategories

This category has the following 11 subcategories, out of 11 total.

CDG |

H |

H cont.LP |

Pages in category "How to"

The following 2 pages are in this category, out of 2 total.