Analysis of Total Iodine

From LEAP

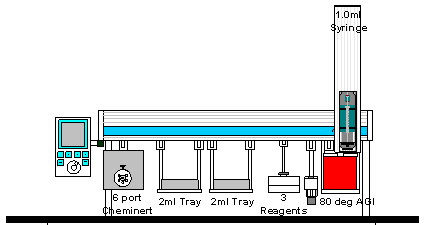

A PAL will be used to mix samples with water, oxidizing hypochlorite and ascorbic acid. Followed by injection to HPLC

After the addition of each reagent to the sample reagent matrix, the 2 ml sample vial will be agitated and heated for a period of time specified by the operator. Once all three reagents have been added to the original sample and each of the agitation periods have been completed, the 2ml sample vial will be transported from the agitator to its original position in the VT-98 destination tray. Then 20ul to 100ul of the sample reagent matrix will be withdrawn from the 2ml sample vial and injected into the 6-port Cheminert valve.

Project Ref: LS-C1001

For other cost/time saving measures consider:

- LEAP offers multiple choices of Valve Self Wash Stations to aid in cleaning the valve [1]

- Dual Channel Serial Injection with Front Cut (M-002) using Analyst and ICC-CE [2]

- Dual Channel Parallel Injection (M-003) using Cycle Composer Software and Analyst [3]

- “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [4]

- Dual Channel Parallel Injection (M-005) using LEAP Shell software [5]

- Summary of LC Multi Valve Applications [6]

- LEAP Shell Software and application for custom injections and scheduling [7]

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.