Dual Channel Sample Cleanup

From LEAP

General Description of process:

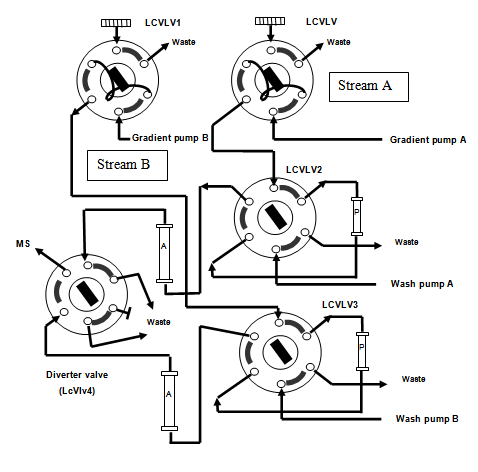

Samples are injected and pass through a guard column which is in-line with the analytical column. At a specified time, the guard column switches out of line and is regenerated using a wash pump configured to do a step gradient while the sample peaks are acquired.

To increase throughput, samples are injected ahead of the acquisition time, so that pre-filtration is occurring concurrently with the previous samples acquisition. Each line of the sample list processes a pair of samples which are staggered in this way.

4 pumps are required: - 2 wash pumps (Agilent 1200) pre-programmed to perform the step gradient and 2 isocratic analytical pumps running continuously one for each column.

Project Ref: H1073b

For other cost/time saving measures consider:

- LEAP offers multiple choices of Valve Self Wash Stations to aid in cleaning the valve [1]

- “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [2]

- Dual Channel Parallel Injection (M-005) using LEAP Shell software [3]

- Summary of LC Multi Valve Applications [4]

- LEAP Shell Software and application for custom injections and scheduling [5]

Contact LEAP

For additional information about this technique please contact LEAP Technologies for detailed information