LEAP Glossary

From LEAP

| LEAP Glossary of Terms |

| Application Type | |

| Glossary | |

| Application ID | |

| _ | |

| Description | |

| Work in progress Glossary of Terms. |

Contents |

Overview

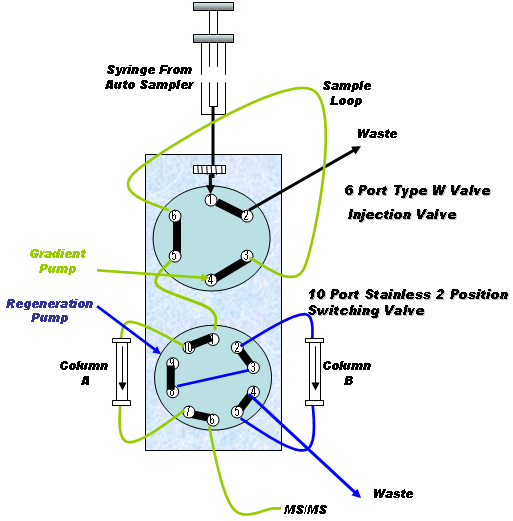

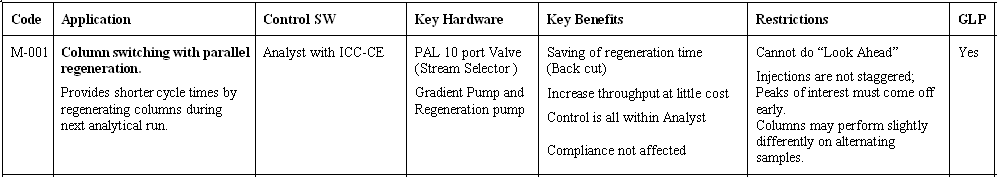

This configuration allows the regeneration of one of the analytical columns while the other one is engaged - giving greater efficiency and higher throughput. This is run directly from within Analyst Software[1] from Applied Biosystems Inc using a Standard LEAP Cycle (requires ICC-CE software) [2].

There are 2 pumps needed, one for the gradient run and another (higher flow rate and isocratic) for regeneration. This configuration requires a 6 port valve for sample loading and a 10 port valve for column switching. Both valves must be controlled by the Standard LEAP cycle. LEAP can not control the MS Selector valve as part of the cycle.

| Key Benefits |

| Saving of Reagent time (Back cut) |

| Increase throughput at little cost |

| Control is all within Analyst Software |

| Compliance not affected |

| GLP Compliant |

| Restrictions |

| Cannot do "Look Ahead" |

| Injections are not staggered |

| Peaks of interest must come off early |

| Columns may perform slightly different on alternating samples |

PRINT Function for Page

For other cost/time saving measures consider:

- LEAP offers multiple choices of Valve Self Wash Stations to aid in cleaning the valve [3]

- Dual Channel Serial Injection with Front Cut (M-002) using Analyst and ICC-CE [4]

- Dual Channel Parallel Injection (M-003) using Cycle Composer Software and Analyst [5]

- “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [6]

- Dual Channel Parallel Injection (M-005) using LEAP Shell software [7]

- LEAP Shell Software and application for custom injections and scheduling [8]

Contact LEAP

For additional information about this technique please contact LEAP Technologies for detailed information

Keyword: Analyst Software, ICC-CE, PAL, 10 port valve, selector valve, injector valve, gradient pump, regeneration pump,back cut, peaks of interest, GLP