NMR Sample Prep

From LEAP

| Line 42: | Line 42: | ||

[[image:Contact_Info.png|40px]] [http://www.leaptec.com/contact-us.php Contact the LEAP office] | [[image:Contact_Info.png|40px]] [http://www.leaptec.com/contact-us.php Contact the LEAP office] | ||

| - | |||

| - | |||

| - | |||

<br><br> | <br><br> | ||

[[Category:LEAP Shell]] | [[Category:LEAP Shell]] | ||

[[Category:Application_Solutions]] | [[Category:Application_Solutions]] | ||

Revision as of 01:30, 21 July 2009

| NMR Sample Prep |

| Application Type | |

| Sample Prep | |

| Application ID | |

| NMR1001 | |

| Description | |

| NMR Sample Prep |

Overview

This Twin PAL application involves the preparation of liquid samples and the transfer of them to NMR tubes. The Sample preparation step consists of adding a selected reagent then incubating the sample vial in a heated agitator for a specified length of time. Once the incubation is completed, the sample vial is returned to the sample tray and a consistent volume of the reacted sample is transferred to sealed NMR tubes. It is applicable to any customer who is doing sample prep and the loading of the NMR tubes. This type of sample prep is a necessary part of the NMR process. The objectives are to have every sample treated the same, maximize throughput, and have a consistent sample volume in the NMR tube.

Significant Markets

This application is ideal for those labs who wish to perform NMR sample prep needing incubation, agitation, and the loading of NMR tubes. Elements of this application could be applied to labs requiring any type of sample prep and maximizing throughput.

What is the sample prep?

The sample prep procedure is quite simple with the exception of the sample needing to end up in NMR tubes and maximizing throughput. Six Inkwell Reservoirs containing the reagents are available to both PAL’s. The user chooses which reagent they want to add and then the samples are loaded into a standard 6 position agitator for heating and shaking. Since the PAL can not easily move NMR tubes, all of the sample prep was done in 10ml vials with ferrous caps and then transferred to the capped NMR tubes at the end of the process. Despite its simplicity, this process requires the manual preparation of many vials at measured times. It can be a very tedious operation which requires a technician to be in the lab doing a very repetitive process. It was important that any automation solution allow for the use of caps &septa and maximize throughput to keep up with the existing NMR’s.

LEAPS Approach

The Challenges for LEAP

The Twin PAL in combination with the LEAP Shell makes a very effective and flexible workstation. We were able to design and provide a solution which met the following challenges from the customer:

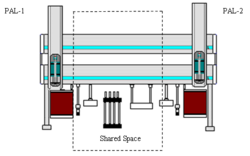

1. Throughput. By using a Twin PAL we are able to take advantage of having both PALs preparing samples by sharing all of the reagents, a sample tray and NMR tube rack.

2. Throughput. Shaking and incubation of a large number of sample vials was accomplished by using two 6 position agitators. LEAP shell provided for maximizing the number of vials in the agitators.

3. Filling a capped NMR tube. This was achieved using a specially designed 32 Position NMR tube holder.

4. Provide the flexibility. LEAP Shell easily allowed the changing of the sample batch size and which reagent was to be used by the operator.

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. We're proud that LEAP is known as a productivity improver for laboratories, and we have big plans to even make government labs in agencies such as FDA, USDA, EPA, FBI, Armed Forces, Homeland Security and others function more efficiently. Robotic sample prep equipment works well in government labs and challenges lab technicians to keep feeding those more samples. Analytical equipment such as chromatographs and mass spectrometers are expensive devices and also expensive to maintain. The least an owner can do is to keep them running and analyze samples around the clock. LEAP has most of its lab automation robots under GSA contract and is eager to service and maintain everything it sells to keep your expensive lab equipment running around the clock. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP