Polymers

From LEAP

| Line 3: | Line 3: | ||

|image = PolymerTwinGC.png | |image = PolymerTwinGC.png | ||

|type = Sample Prep and Inject | |type = Sample Prep and Inject | ||

| - | |id = | + | |id = Polymers 001 |

|description = Polymer Analysis | |description = Polymer Analysis | ||

}} | }} | ||

Revision as of 16:34, 9 February 2009

| Polymers |

| Application Type | |

| Sample Prep and Inject | |

| Application ID | |

| Polymers 001 | |

| Description | |

| Polymer Analysis |

Overview

Chemical analysis of polymers, as well as other forms of analysis such as viscosity and other tests are a necessary part of polymer development, as well as QC processes during manufacture. Polymers are generally solids when in the final product, and thus are not amenable to such analysis unless they can be first liquefied. Preparation for analysis requires multiple stages of treatment frequently with heated reaction and cooling steps prior to introduction into a detector such as a GC. Such processes are lengthy, time-critical and labor intensive to perform manually. They frequently involve handling of caustic or toxic reagents. There is a strong case therefore, for automation of such processes.

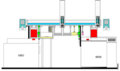

LEAP has broken new ground in one such application, where the complexities of this type of sample preparation have been fully automated using an HTX2H in the configuration shown below:

Significant Markets

- Polymer Manufactures

- Biodiesel Blenders

- Polymer Distributors

- Polymer End Users

What is a Polymer experiment?

The sample preparation process involves 2 heated reactions with cooldown steps in between. The first hydrolyses the solid polymer in a mixture with an internal standard at high temperature in Agitator 1. The pellets dissolve and after a quenching reaction and cooldown period, a derivitizing reagent is added followed by another heated incubation at lower temperature. The reactants are then injected onto a GC for analysis.

A balance is used to check that a minimum weight of product is in the original vial. If not, the sample is skipped. The samples are barcoded at the time the sample list is set up. At runtime the scanned barcode is compared to the expected barcode and if there is a mis-match then the sample is also skipped. .

LEAP Shell handles the sample scheduling of each of the 5 stages of the process, overlapping them all and filling up both agitators according to the available time between operations. It also handles barcode and weight validation as well as data logging.

LEAPS Approach

• Twin PAL control using a single sample list in LEAP Shell.

• Two heated zones for different temperature reactions.

• Direct injection to either of two GCs.

• Balance integration for weighing of solid product and internal standard.

• Up to 8 reactant vessels, and 32 sample vial capacity.

• Overlapped staggered processing of all samples for high throughput.

• Barcode checking, mismatched vials are not processed.

• Weight checking, over or under weight vials are skipped.

• Data reporting to log files.

• GC failsafe mode – if GC goes down during a run, samples are still processed.

• Integrated with Chemstation.

Market potential:

The success of this initial installation shows LEAP’s capability to solve complex automation challenges in areas which have previously been out of our reach. The polymer industry presents opportunities to expand these types of sales, not only for these complex sample preparation applications for solids, but for simpler applications such as viscosity testing or sample prep for NMR.

In more general terms, this application illustrates the power of LEAP Shell and the new capabilities it provides which can be applied much more widely. Consideration should be given to the following opportunities:

• Handling of single or multiple overlapped incubations e.g. Headspace or SPME.

• Extensive customization of the Sample list.

• Open access – walk-up addition of samples during a run.

• Extensive use of the “IF” statement to manage error conditions and determine criteria for sample processing or not.

• Output of data to log files for record keeping or for integration with data systems.