Sample Filtration with LEAP X-Press

From LEAP

Current revision (18:30, 9 June 2010) (view source) |

|||

| (One intermediate revision not shown.) | |||

| Line 33: | Line 33: | ||

* [http://www.leapwiki.com/mediawiki/index.php?title=Summary_of_LC_Multi_Valve_Applications Summary of LC Multi Valve Applications ] | * [http://www.leapwiki.com/mediawiki/index.php?title=Summary_of_LC_Multi_Valve_Applications Summary of LC Multi Valve Applications ] | ||

* [http://www.leaptec.com/software/leap-shell-3.php LEAP Shell Software and application for custom injections and scheduling ] | * [http://www.leaptec.com/software/leap-shell-3.php LEAP Shell Software and application for custom injections and scheduling ] | ||

| + | ---- | ||

| + | === Videos of PAL === | ||

| + | <br> | ||

| + | [[Image:Movie Icon.png|40px]] | ||

| + | [http://www.youtube.com/user/LEAPTechnologies#g/u LEAP's PAL Application Videos on YouTube] | ||

| + | <br> | ||

| + | [[Image:LEAP.jpg|800px|center|LEAP X-Press WorkStation Brochure page 1]]<br> | ||

| + | [[Image:LEAP_001.jpg|800px|center|LEAP X-Press WorkStation Brochure page 2]]<br> | ||

---- | ---- | ||

{{logo}} | {{logo}} | ||

Current revision

General Description of the Application

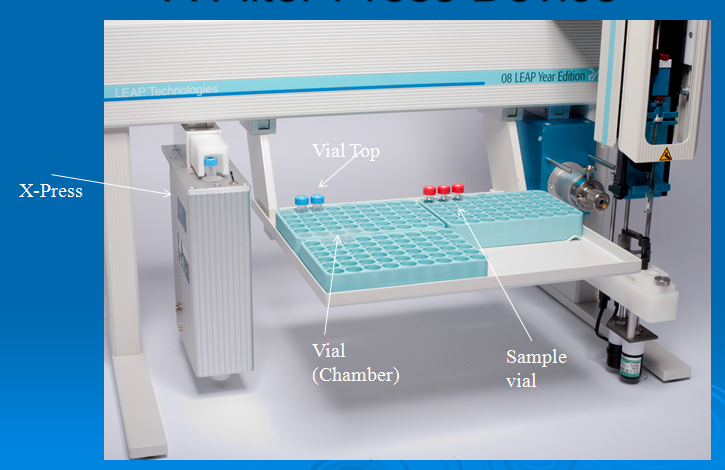

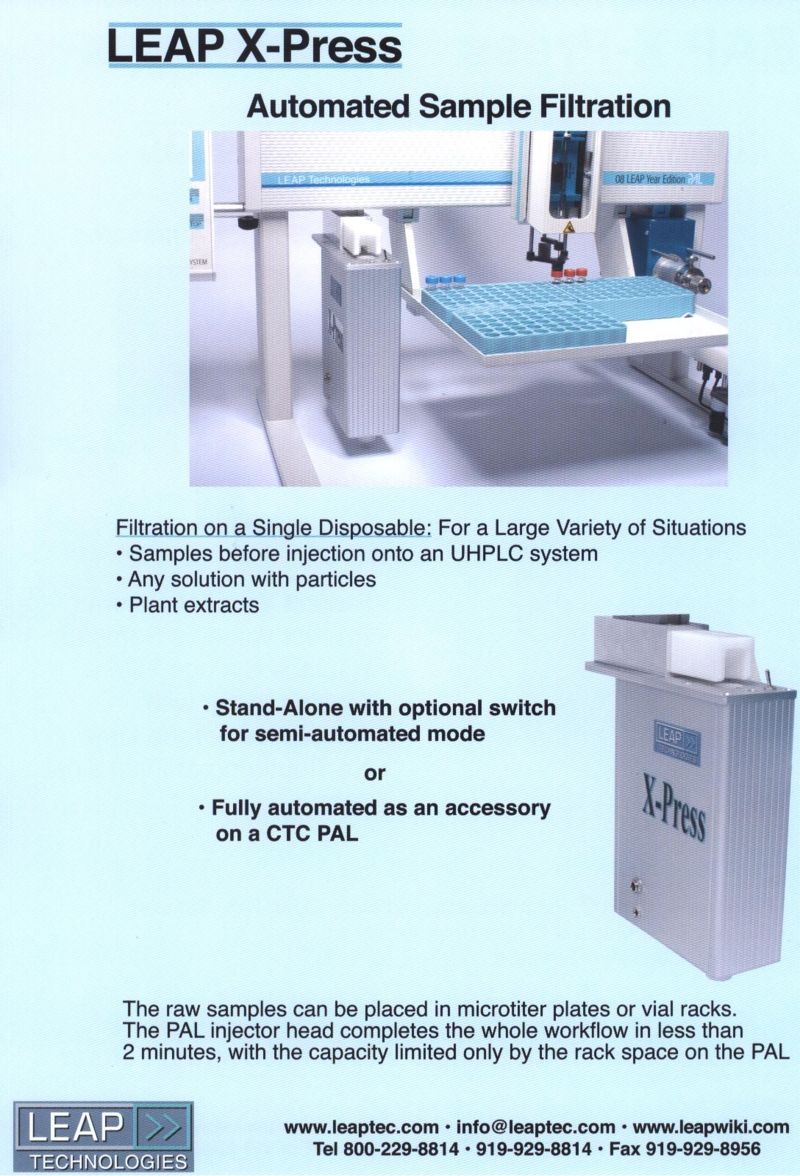

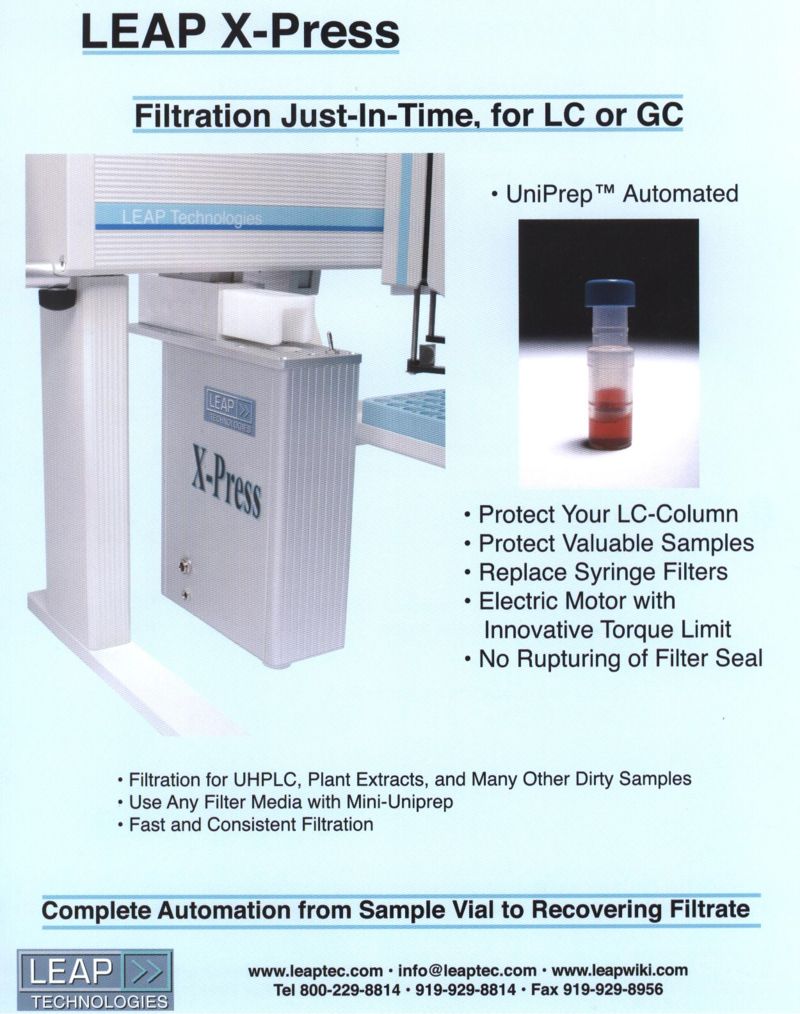

A fully automated sample prep system which is run unattended 24/7. Samples from a larger robotic system are presented in pairs to the PAL. The PAL is triggered by a contact closure to pick up the sample and read an associated information file. One of the sample pairs is filtered using the Whatman Mini-Uniprep filters . LEAP has developed a Press , LEAP X-Press , which automates this step. Sample pairs are injected onto two different valves each hooked up to a HPLC system controlled by EZChrom.

The PAL system is controlled by LEAP Shell (version 3.0).

A pair of 2oz sample bottles will be transferred into the tray holder by an existing robotic system . One contains the assay sample and the other contains the HCB sample. The assay sample will be transferred into a 2 mL vial. The HCB sample will be transferred into a Mini-Uniprepchamber, PAL will pick the filter plunger and insert into the chamber and transfer them into the LEAP X-Press . After the filtration, the Mini-Uniprep vial will be brought back to the tray holder. Two LC systems are connected to the PAL, one for the assay sample and the other for HCB. Whenever either one of them is ready, the next prepared sample from the tray holder will be injected into the LC valve. A blank sister control from a 20 mL bottle will be processed before each assay sample.

All processing information will be written into an Excel output file.

Project Ref: LS-H1008

Contents |

Video

Additional LEAP Wiki info on press

![]() Additional info on LEAP-XPress

Additional info on LEAP-XPress

Whatman Information Document

For other cost/time saving measures consider:

- Summary of LC Multi Valve Applications

- LEAP Shell Software and application for custom injections and scheduling

Videos of PAL

![]() LEAP's PAL Application Videos on YouTube

LEAP's PAL Application Videos on YouTube

LEAP strives to find total solutions for analytical lab automation by automating analytical processes for small and large molecules in extracted liquids, solids, and recently in human, animal and plant tissues. We provide the precise robotics and efficient sample prep required by modern measurement techniques such as MALDITOF mass spectroscopy. Our newest specialty customization of CTC Analytics’ PAL features small workstations that can perform complex liquid handling tasks including HPLC-Purification, SPE, filtration, weighing, heating and stirring. They can be configured as stand alone units or integrated for “just in time” sample prep for LC-MS or GC-MS analysis.

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |