Purific

From LEAP

(→Peak Harvester Control Software) |

(→Peak Harvester Control Software) |

||

| Line 53: | Line 53: | ||

2) Peak-Based mode using an analog signal e.g. UV or ELSD detector<br> | 2) Peak-Based mode using an analog signal e.g. UV or ELSD detector<br> | ||

3) Mass-triggered mode using an output signal of the MS for mass fractionation<br> | 3) Mass-triggered mode using an output signal of the MS for mass fractionation<br> | ||

| - | |||

| - | * Color coded sample and fraction tracking lets you review and report an enormous amount of analytical data. It shows how many fractions have been collected and where they are located in the collection tray. | + | * Color coded sample and fraction tracking lets you review and report an enormous amount of analytical data. It shows how many fractions have been collected and where they are located in the collection tray. [[image:3_modes_of_detection.png|300px|thumb|right|Peak Harvester modes]] |

| + | |||

* Advanced software algorithms allow collecting the fractions correctly even for challenging peak shapes. | * Advanced software algorithms allow collecting the fractions correctly even for challenging peak shapes. | ||

Revision as of 18:02, 1 July 2010

| Purific |

| Application Type | |

| STANDARD LEAP PRODUCT | |

| Application ID | |

| Description | |

| Purific controlled by Peak Harvester |

Contents |

Overview

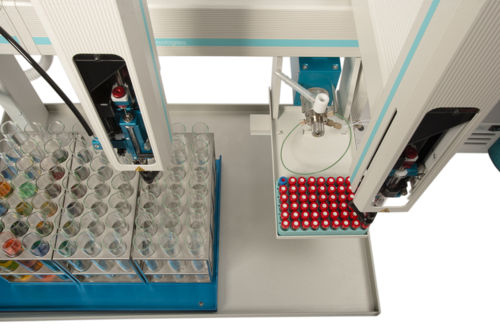

The Purific™ is the latest fully automated turnkey system from LEAP Technologies for isolating target compounds from complex samples. It is compatible with a wide range of sample sizes and a wide range of HPLC columns.

Peak Harvester™ software is used for the preparation and fractionation that coordinates the injection, data handling, collection and reporting to create an integrated system. The collector's unit, the pumps, detectors, and the data acquisition are implemented as individual systems within a single software package. The central component is the PAL robot and all other devices can be either directly controlled by the PEAK HARVESTER or synchronized with injection and collection by contact closure.

Key Benefits:

- Powerful. Automation saves time without compromising purification quality.

- Get excellent sample recovery in less time with much less effort…

- User Friendly. The intuitive software interface makes setup and record keeping easy

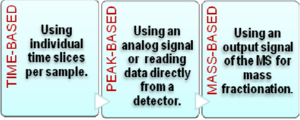

- Versatile. Time-Based, Peak-Based, Mass-triggered collection

Applications

- Purification for biological or sensory evaluation (e.g. DMPK)

- Replace anitquated purification systems

- Scale Up and Key synthetic intermediate recvoery

- Flash chromatography capable

The Purific combines LEAP’s strengths in LC sample preparation and purification to enhance productivity for analytical chemist.

- Dual head minimizes carryover and increases throughput

- Syringe only concept. No error prone Teflon tubing or transfer lines

- Precise sample handling for dependable purification results

- All in one Injector-Collector, Compact Ergonomic Design features a small footprint that fits easily into a standard fume hood

- Anti-Static solvent Lines

- Automated switching procedures to clean and equilibrate column to increase throughput. (Requires optional 10-port valve)

- Performance with Maximum Flexibility

- Keep your samples cool, up to 4°C, with optional cool stack

Peak Harvester Control Software

Peak Harvester™ Developed by Leap Technologies is specifically designed to control each single step of the purification process. LEAP owns and writes the software. Rely on direct communication with the software team.

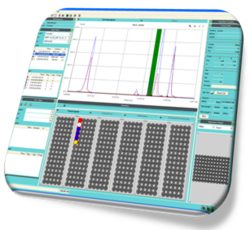

It allows control of the LC pumps and detector, collects fractions in manual mode or in a choice of three programmable modes inside a predetermined collection window:

1) Time based mode using individual time slices per sample

2) Peak-Based mode using an analog signal e.g. UV or ELSD detector

3) Mass-triggered mode using an output signal of the MS for mass fractionation

- Color coded sample and fraction tracking lets you review and report an enormous amount of analytical data. It shows how many fractions have been collected and where they are located in the collection tray.

- Advanced software algorithms allow collecting the fractions correctly even for challenging peak shapes.

PeakHarvester™ software incorporates an open access interface that lets you walk up and log in your samples anytime. First simply log into the software using your ID followed by the format of the samples. Choose the method you want to use from a set of method options. After the collection process, review your results and retrieve the purified samples. PeakHarvester™ contains complete system administration tools for secure access management. All activities are stored in log files to ensure system security reducing the possibility of errors and subsequent losses of potentially precious materials. Peak Harvester™ tracks barcodes and accepts sample list in either CSV or XML and interfaces easily with LIMS systems with XML report capability

- Specifically designed to control every step of the purification process.

- Quickly create and customize new methods.

- ”Smart” fraction collection on two signals simultaneously: Time and/or slope and/or threshold.

- Repeat injection can be collected into same fraction sites.

- Color coded sample and fraction tracking lets you review and report an enormous amount of analytical data.

- Open access interface lets you walk up and log in your samples anytime.

- Accepts sample lists in CSV or XML formats.

- Barcode capable.

- Choice of collection patterns.

- Inject or re‐inject from and collect to aaccessible racks or stacks.

- Automatic end of collection feature can reduce solvent consumption.

- Detect and cancel signal noise.

- UV Wavelength settings integrated into the sample method.

- Remove collection rack and add samples during the run for 24/7 operation.

- Error handling and monitoring system.

THE HPLC WITH UNIQUE UV‐Vis DETECTOR

- Wide range of flow rates (0.01‐100ml/min); virtually all application needs are covered.

- Smooth, precise solvent flow and system pressure are maintained with a built‐in pulse-dampener and pressure unit.

- User friendly pump heads are self‐contained and can be rapidly exchanged.

- Flow accuracy: ±1% of selected flow rate or ±0.05% of maximum flow rate, whichever is larger (0.1% for 5 mL heads).

- Flow reproducibility: ±0.1% of selected flow rate or ±0.05% of maximum flow rate, whichever is larger (0.1% for 5 ml heads).

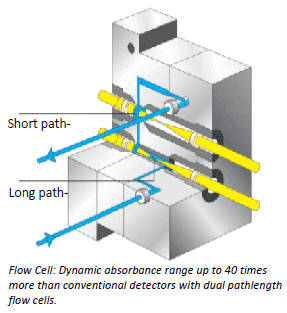

- From 190 to 900nm with drift less than 1 mAU/hr. The detector delivers a superb sensitivity and a wide dynamic range.

- Routine maintenance is easy with front panel access. Thumb screws secure the lamps and flow cells making access and exchange tool free.

- Two independent channels and available analog‐to‐digital conversion for 3rd party detector integration (eg: ELSD, MS)

Extended Range Operation: The detector constantly samples both beams and records offset constants, even in analytical operation. Because of this, the detector has in memory the necessary constants to mathematically scale and seamlessly extend long path response with the short path response. During extended range operation, the long pathlength is constantly sampled, and as absorbance decreases there is a seamless switch back to dual beam operation in normal range.

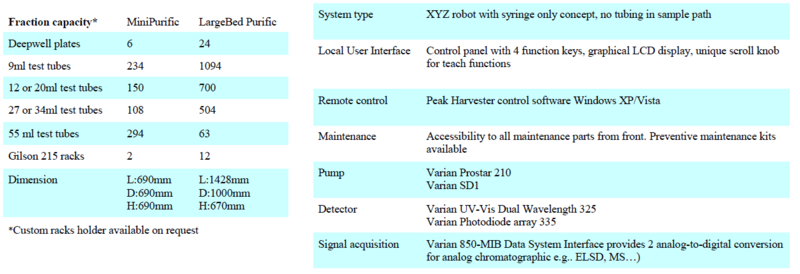

Purific General Specifications

Configurations and Screenshots

Other Reference Material

Accessories for the PAL

![]() Cooling &Heating Sample Storage

Cooling &Heating Sample Storage

![]() Active Self Wash for valve and syringe

Active Self Wash for valve and syringe

Videos of PAL

![]() Purification Video on YouTube

Purification Video on YouTube

![]() LEAP's PAL Application Videos on YouTube

LEAP's PAL Application Videos on YouTube

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |