Rapid Precision Dispensing

From LEAP

(Difference between revisions)

| Line 20: | Line 20: | ||

For additional information about this technique please contact LEAP Technologies for detailed information | For additional information about this technique please contact LEAP Technologies for detailed information | ||

| - | + | [[image:Contact_Info.png|40px]] [http://www.leaptec.com/contact-us.php Contact the LEAP office] | |

<br><br> | <br><br> | ||

[[Category:LEAP Shell]] | [[Category:LEAP Shell]] | ||

| + | [[Category:Example Solutions]] | ||

Revision as of 14:53, 9 June 2009

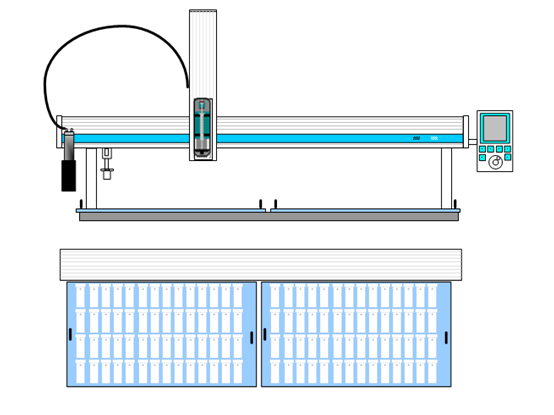

An extended rail PAL is used to perform precise and rapid loading of 1 ul volumes onto a customer material for off-line analysis. Over a hundred customer target material is loaded on to 2 trays.

1 ul of solvent is delivered at high precision using a pump and a side port syringe to each target approximately every 5 seconds.

LEAP Shell software allows control of each tray to allow one to be loaded/ unloaded while the other is in process or complete walk away sample processing of both trays.

For other cost/time saving measures consider:

- Summary of LC Multi Valve Applications [1]

- LEAP Shell Software and application for custom injections and scheduling [2]

Contact LEAP

For additional information about this technique please contact LEAP Technologies for detailed information