Micro Extraction by Packed Sorbent

From LEAP

(→Overview) |

|||

| Line 55: | Line 55: | ||

<br><br> | <br><br> | ||

[[Category:Accessories]] | [[Category:Accessories]] | ||

| + | [[Category:SPE]] | ||

Revision as of 00:52, 5 May 2009

| SPE Applications |

| Application Type | |

| STANDARD AND SPECIAL | |

| Application ID | |

| MEPS | |

| Description | |

| Micro Extraction by Packed Sorbent (MEPS) |

Contents |

Overview

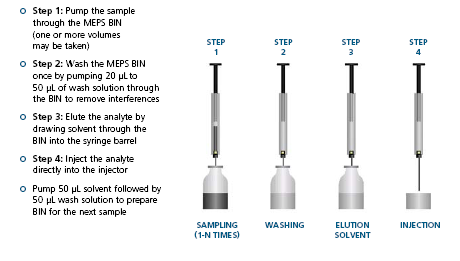

Micro Extraction by Packed Sorbent* (MEPS) is a new development in the field of sample preparation by solid phase extraction (SPE), and is a result of a collaboration between SGE and Mohamed Abdel-Rehim (AstraZeneca) and Lars G. Blomberg (University of Karlstead) Automation of MEPS is accomplished with the PAL Series of CTC Autosamplers. MEPS is the miniaturization of conventional SPE packed bed devices from milliliter bed volumes to microliter volumes. The MEPS approach to sample preparation is suitable for reversed phases, normal phases, mixed mode or ion exchange chemistries. MEPS is available in a variety of common SPE phases. The cartridge (Patent Pending) contains the stationary phase, and is built into the syringe needle. With a typical void volume of a few μL, the MEPS elution is compatible with GC and LC inlets making it ideal for automated on-line SPE on the CTC PAL platform. MEPS kits are exclusively available worldwide through LEAP Technologies and SGE Analytical Science.

MEPS performs the same function as SPE, namely the purification or speciation of samples, but with some significant differences:

- MEPS works with much smaller samples (as small as 10µL) than full scale SPE

- MEPS can be fully automated – the sample processing, extraction and injection steps are performed on-line using the same syringe

- MEPS is applicable to GC and LC

- Significantly reduces the volume of solvents and sample needed

MEPS for PAL Systems is distributed by SGE & LEAP Technologies.

Available for both GC & LC applications.

Photos

More Info

MEPS web site by SGE including product brochure

Contact LEAP

For additional information about this technique please contact LEAP Technologies for detailed information