Rapid Precision Dispensing

From LEAP

(Difference between revisions)

(New page: An extended rail PAL is used to perform precise and rapid loading of 1 ul volumes onto a customer material for off-line analysis. Over a hundred customer target material is loaded on to 2 ...) |

|||

| Line 1: | Line 1: | ||

An extended rail PAL is used to perform precise and rapid loading of 1 ul volumes onto a customer material for off-line analysis. Over a hundred customer target material is loaded on to 2 trays. | An extended rail PAL is used to perform precise and rapid loading of 1 ul volumes onto a customer material for off-line analysis. Over a hundred customer target material is loaded on to 2 trays. | ||

| - | 1 ul of solvent is delivered at high precision using a pump and a side port syringe to each target approximately every | + | 1 ul of solvent is delivered at high precision using a pump and a side port syringe to each target approximately every 5 seconds. |

LEAP Shell software allows control of each tray to allow one to be loaded/ unloaded while the other is in process or complete walk away sample processing of both trays. | LEAP Shell software allows control of each tray to allow one to be loaded/ unloaded while the other is in process or complete walk away sample processing of both trays. | ||

Revision as of 19:39, 24 April 2009

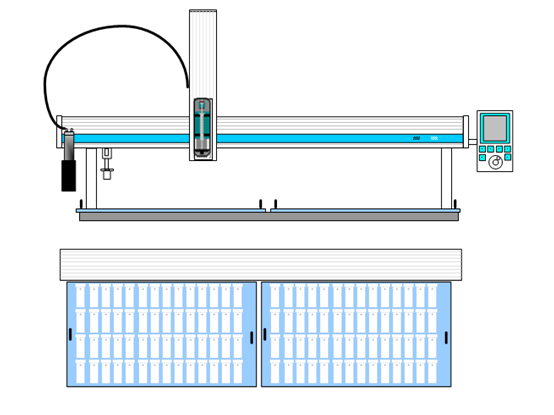

An extended rail PAL is used to perform precise and rapid loading of 1 ul volumes onto a customer material for off-line analysis. Over a hundred customer target material is loaded on to 2 trays.

1 ul of solvent is delivered at high precision using a pump and a side port syringe to each target approximately every 5 seconds.

LEAP Shell software allows control of each tray to allow one to be loaded/ unloaded while the other is in process or complete walk away sample processing of both trays.

Contact LEAP

For additional information about this technique please contact LEAP Technologies for detailed information